What Is Laser Cutting In Sheet Metal?

Across metalworking and fabrication, laser cutting provides a strong level of precision, allowing manufacturers to make sure their work stays within the required tolerance. With that in mind, here’s a guide to the use of laser cutting in sheet metal projects.

What Is Laser Cutting?

Laser cutting is the use of a high-power laser to shape and cut metals into a certain pattern. This process uses computer numerical control (CNC) to guide the laser along a specific path of coordinates, which ensures there are no human errors during the cutting stage. Computer control allows for a more intricate design, with minute details that other forms of cutting usually struggle with.

The process for sheet metal is vaporisation cutting, where the laser melts the

metal into a certain shape, while pressurised gas removes the waste this produces. Different laser cutters operate under different principles – a flying optic cutter moves the laser while a moving material cutter moves the metal. Hybrid cutters, meanwhile, can move both at the same time. No matter the cutter type, lasers provide high-quality, flexible, and precise cuts.

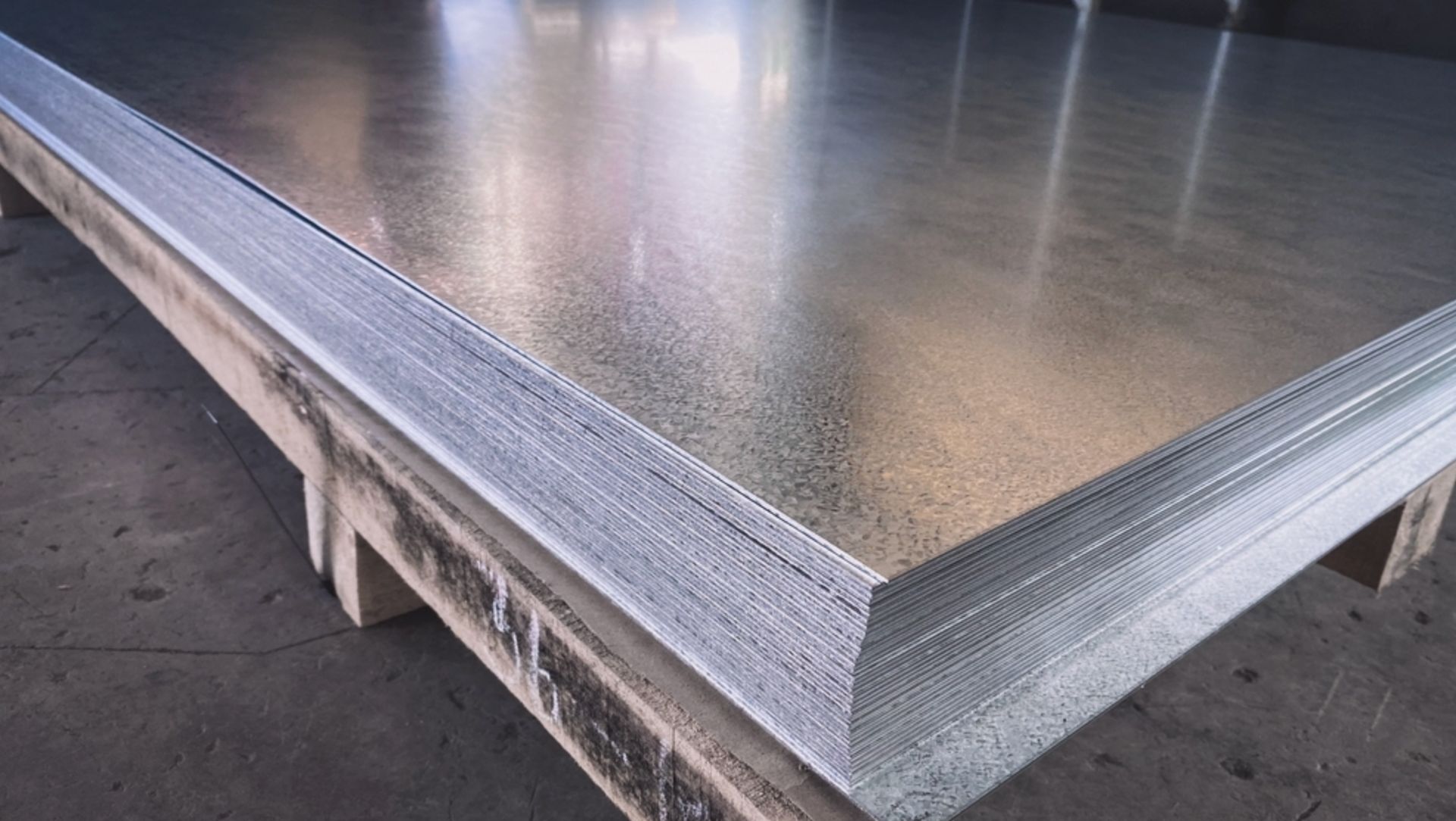

What Kinds Of Sheet Metal Can Lasers Cut?

Laser technology has been growing for decades, and today it stands as a powerful cutting instrument, able to pierce different kinds of sheet metal with ease. As for the specific metals these machines work best with, they effortlessly handle mild steel, carbon steel, stainless steel, aluminium, and many other steel alloys; this versatility is part of why the process is so popular.

In determining the maximum thickness that a laser can penetrate, there are many factors at play, including the laser’s specific wattage and the nature of this particular metal, as different alloys have different strengths. For example, lasers working at 6,000 watts could cut through about 7 centimetres of stainless steel, but a stronger laser cutter would obviously cut through more.

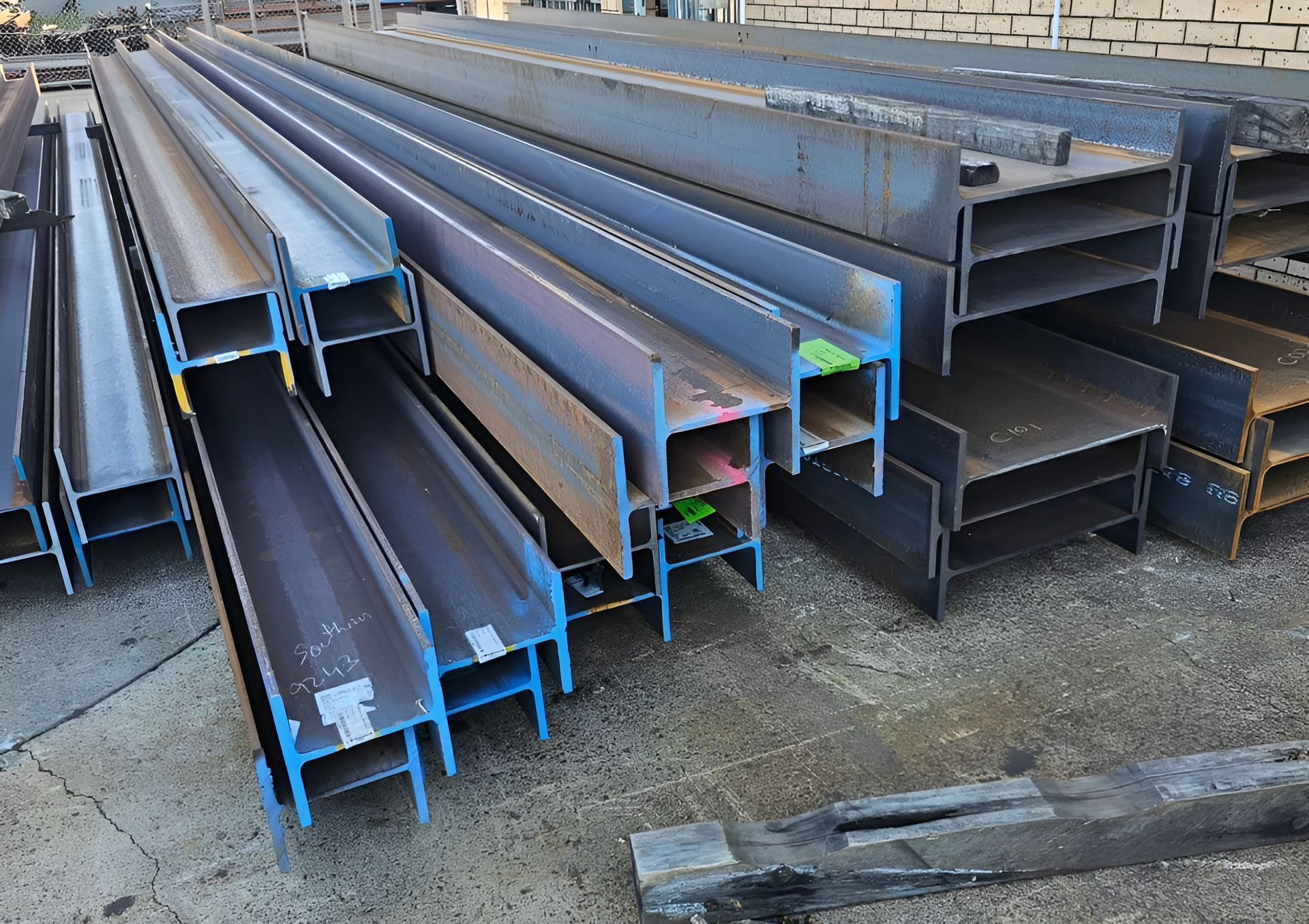

Which Projects Can Use Laser Cutting?

Many kinds of metal projects can use laser cutting. For example, some may use it to create steel tools such as hammers, spades, or even axes. Laser cutting can even produce high-quality engravings or drawings, as well as stencils for future use. Construction projects also use steel for structural supports; laser cutting ensures these stay within the right tolerances.

Everything from utensils to metal detectors, trolleys, truss plates and more has components that use laser cutting to form exact shapes. For that reason, it’s important you select a high-quality service that can fashion any component you need to a high standard, leaving you with a clean cut every time.

At On the Spot Steel Fabrication, we make use of laser cutting to facilitate a range of sheet metal projects. We have been hard at work for over a decade and always devote ourselves to giving you the metal fabrication you need. Contact us today for more information about our services and to get a free quote.