Blog > A Guide To The Process Of Sheet Metal Fabrication

A Guide To The Process Of Sheet Metal Fabrication

Have you ever wondered how the metal parts and structures around us are made? Think about the sleek body of your car or the durable appliances in your kitchen. The process behind these essential parts is known as sheet metal fabrication. It is a comprehensive process involving the cutting, shaping and assembling of metal sheets into various structures and products. In this blog, we'll explore the key stages, techniques and considerations involved in sheet metal fabrication to help you make informed decisions.

The Significance of Metal Fabrication in Various Industries

Metal fabrication’s significance spans multiple industries, each leveraging its precision and adaptability to meet specific needs.

Automotive Industry

The precision and adaptability of metal fabrication make it crucial for producing the diverse and complex components required in the automotive industry.

Construction

In construction, metal fabrication offers the strength, durability and flexibility needed to create buildings, bridges and infrastructure.

Consumer Goods

From appliances to electronics, metal fabrication is key in designing and manufacturing durable and functional products that enhance consumers’ daily lives.

Key Stages Of Sheet Metal Fabrication

Sheet metal fabrication is not a one-size-fits-all process; it comprises several key stages, each critical to achieving the desired outcome. These stages include:

- Design and Development: Crafting detailed plans and specifications for the final product.

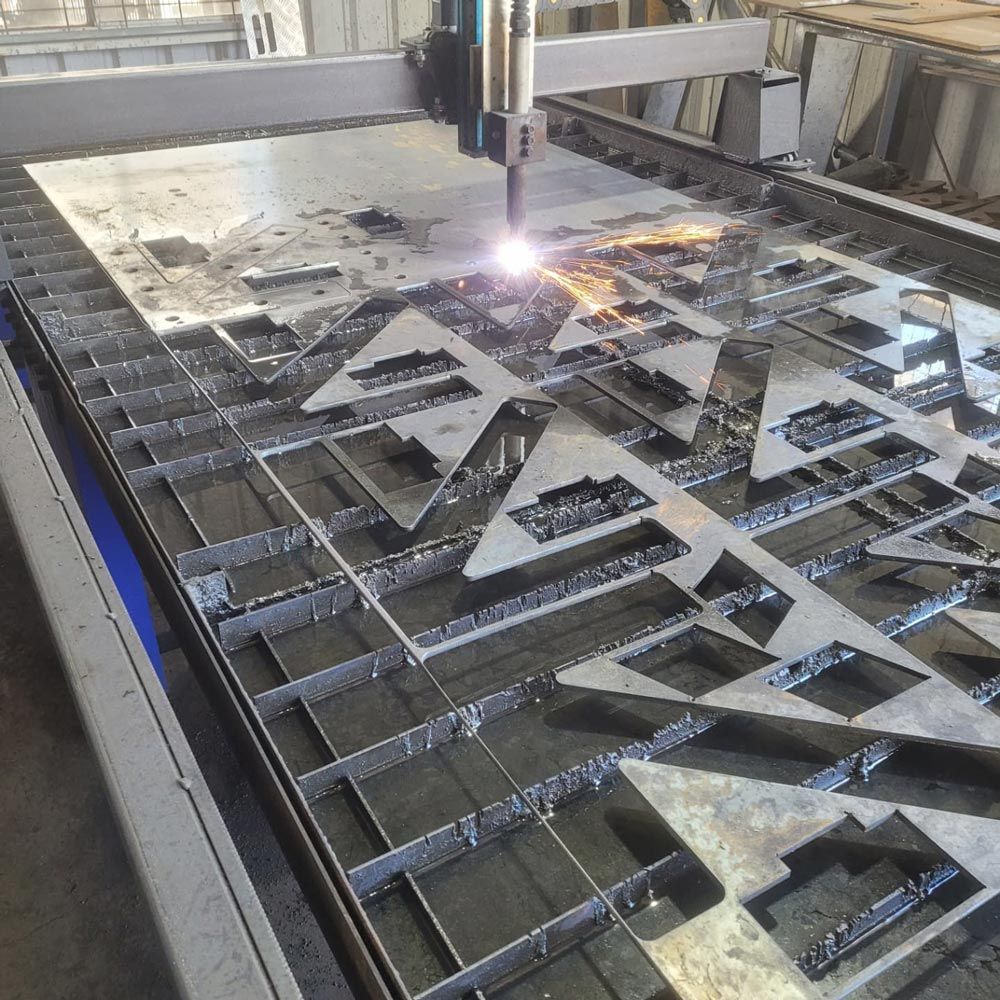

- Cutting: Using techniques like laser cutting or water jetting to cut the metal sheet into the initial shape.

- Forming: Shaping the cut metal through bending, stamping or pressing.

- Assembly and Welding: Joining the shaped pieces to form the final product.

- Finishing: Applying finishes such as painting, powder coating or plating to protect and enhance the appearance of the metal.

Advanced Techniques And Considerations

The evolution of sheet metal fabrication technology has introduced advanced techniques that offer greater precision, efficiency and customisation. Let’s explore some of these advancements and the considerations that guide the fabrication process.

Choosing the Right Material

Selecting the appropriate material is crucial for ensuring the performance and durability of the final product. Factors such as the intended use, environmental conditions and cost all play a role in this decision-making process.

Quality Control Measures

Implementing strict quality control measures throughout fabrication is essential for maintaining accuracy and consistency. This measure includes regular inspections and testing to meet industry standards and customer expectations.

The Future of Fabrication Technologies

The sheet metal fabrication industry continues to innovate, incorporating technologies such as 3D printing and automated robotics to enhance precision and efficiency. Staying abreast of these advancements allows for exploring new possibilities in design and manufacturing.

Elevate Your Project with Our Steel Fabrication Excellence

Sheet metal fabrication is a multifaceted process that requires careful planning, precise execution and comprehensive finishing. Its versatility makes it indispensable in creating durable, high-quality products across various industries.

At On The Spot Steel Fabrication, we pride ourselves on delivering high-quality steel fabrication services catering to various needs. Whether it's intricate components for the automotive industry, bespoke structures for construction or custom fittings for domestic projects, our team of skilled professionals is equipped to handle challenges of any scale. If you are searching for steel fabrication on the Sunshine Coast, contact us today.